KabVision is the business unit specialising in the study, development and supply of vision systems customised to the needs of the application, in the creation of neural networks applicable to machine vision systems and in the development of augmented reality systems for smart manufacturing.

We guarantee a design and consultancy service for the development of the machine vision system best suited to the customer’s specific needs.

They can be easily integrated into production lines or machinery because the hardware used does not require a special protected environment, and thanks to neural networks, changeover will no longer be necessary when working on a single recipe.

We have a machine vision laboratory equipped with different types of cameras, optics and illuminators, where R&D studies new innovative solutions or where we test the problems of companies that send us their products.

The application of innovative machine vision and the opportunity to adapt it to customised applications of high complexity generates endless possibilities in the field of industrial automation and beyond.

Customised, turnkey projects.

We use computer vision to solve applications for optical character recognition (OCR), robot guidance, code reading, positioning control, 2D and 3D measurements, and quality control in all industries through object detection, image classification, image segmentation, etc.

Combining artificial intelligence and machine vision to solve complex visions.

K-VISION Software

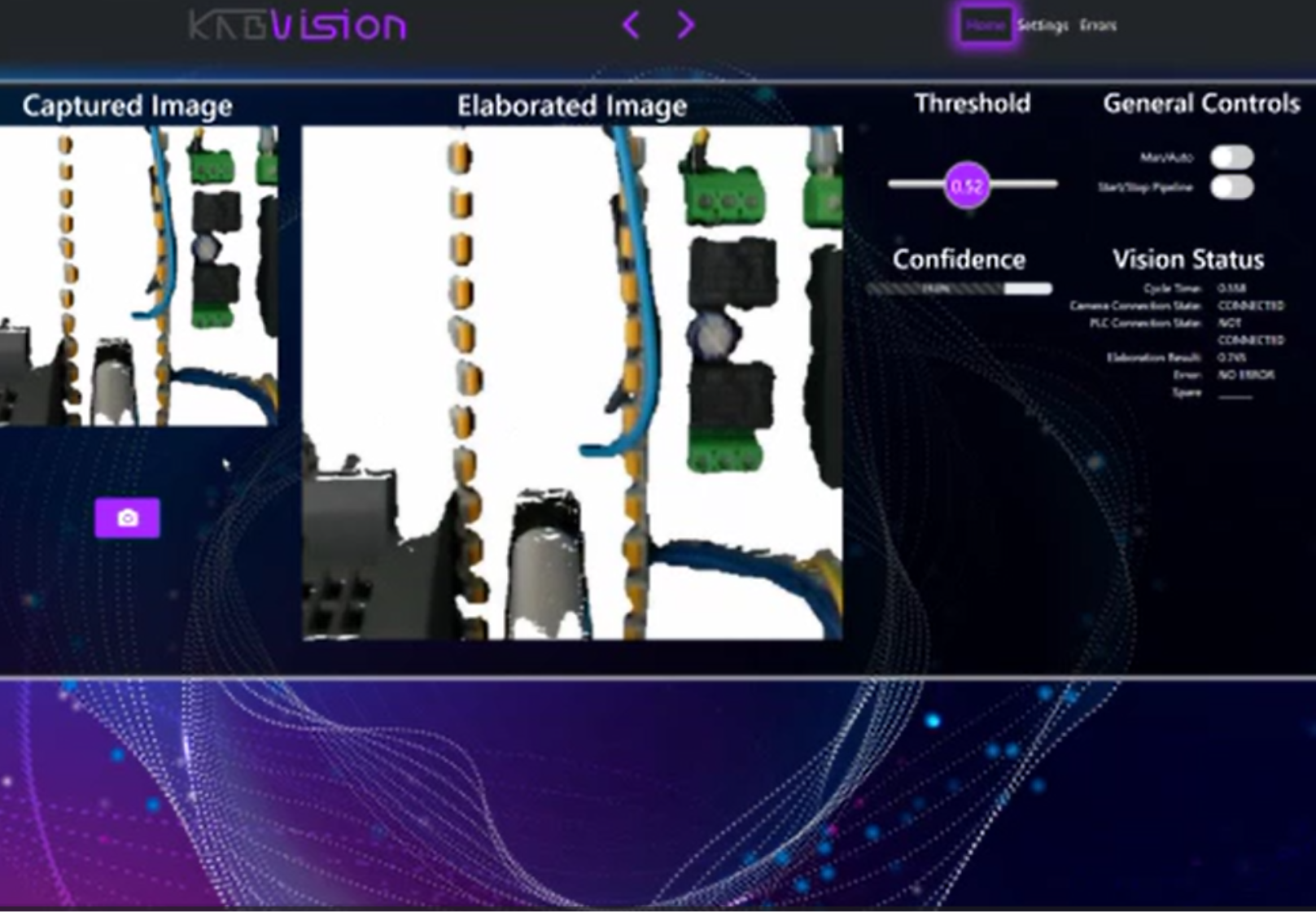

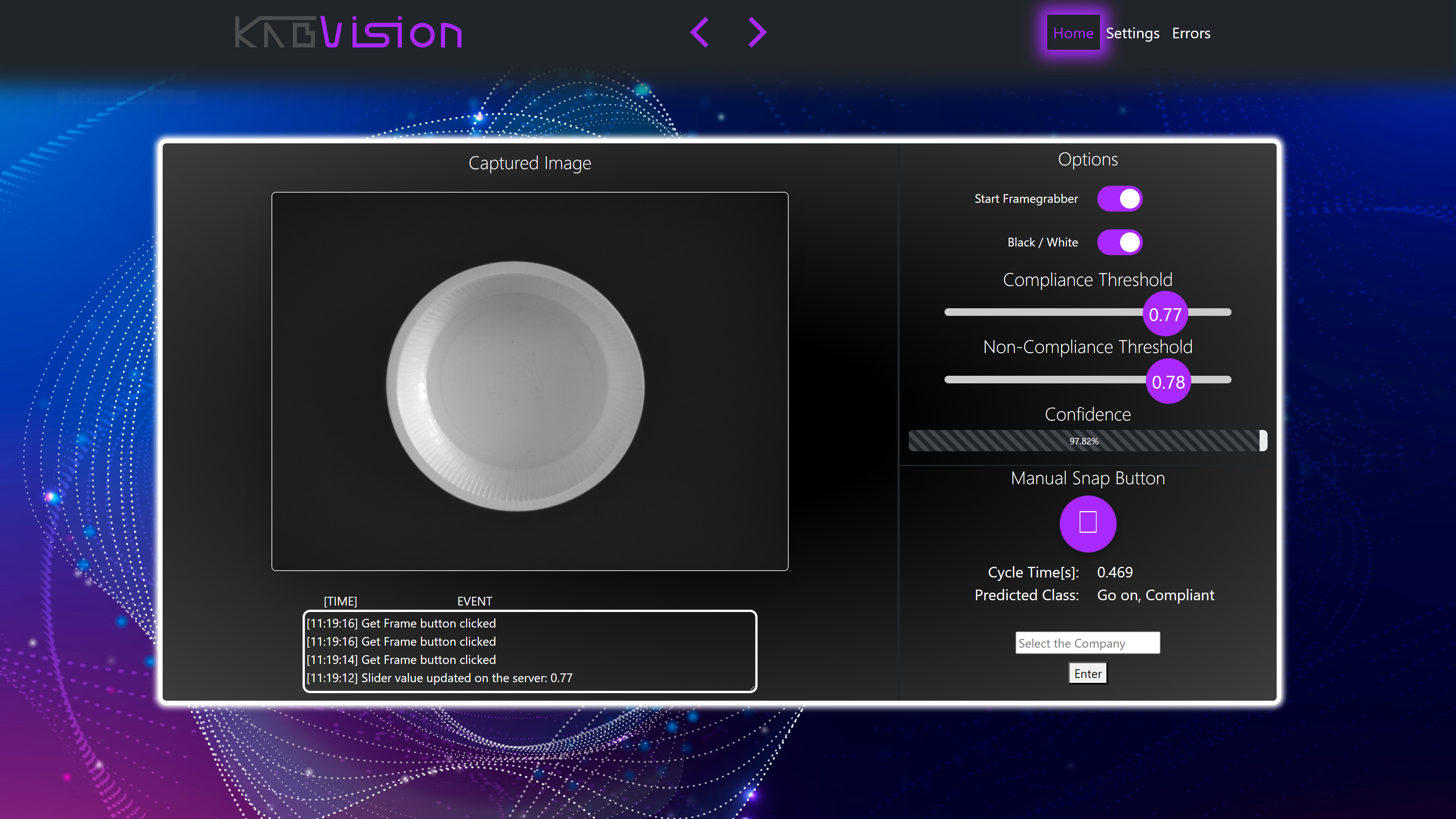

The vision systems we develop are based on our K-VISION platform, a software with advanced functionalities for the supervision, monitoring and control of industrial processes. It integrates different vision technologies and automation devices.

Based on constantly updated neural networks, K-VISION acquires images and processes them as required. Flexible and scalable, it trains for every type of application.

It automates tasks that are too complicated and time-consuming to programme with rule-based algorithms, while ensuring consistency and speed that are impossible with manual inspection.

SMART interface

Through the software and its easy-to-use interface, operators will be able to visualise the captured images in real time, decide whether the inference will be manual or automatic depending on the working mode, set thresholds for the interpretation of the result, manage the settings for image capture and manage their backup.

KabVision’s goal is to create sustainable innovation paths that can ensure superior production quality, reduce waste and costs in every industry.

Optimising resources and increasing production capacity

Raising the value of human capital

Competitiveness in the industry

Ease of use

Discover our machine vision technologies

KabVision develops easy-to-use and scalable robot guidance vision systems to operate in high-precision manufacturing industrial environments with automated learning, automatic calibration, picking and tracking phases.

K – ROBOT

AI machine vision system for robot guidance

Uses software and cameras to locate the position of components to be processed and then guide the robot in its movements.

KabVision develops vision systems for quality control that can be integrated with automatic inspection, measuring and sorting machines or stand alone for the identification of quantitative and qualitative defects, with the aim of zeroing the presence of rejects or defects in products.

K – QUALITY

AI machine vision system for quality control

Thanks to the power of neural networks it enables different inspections and applications.