Technology

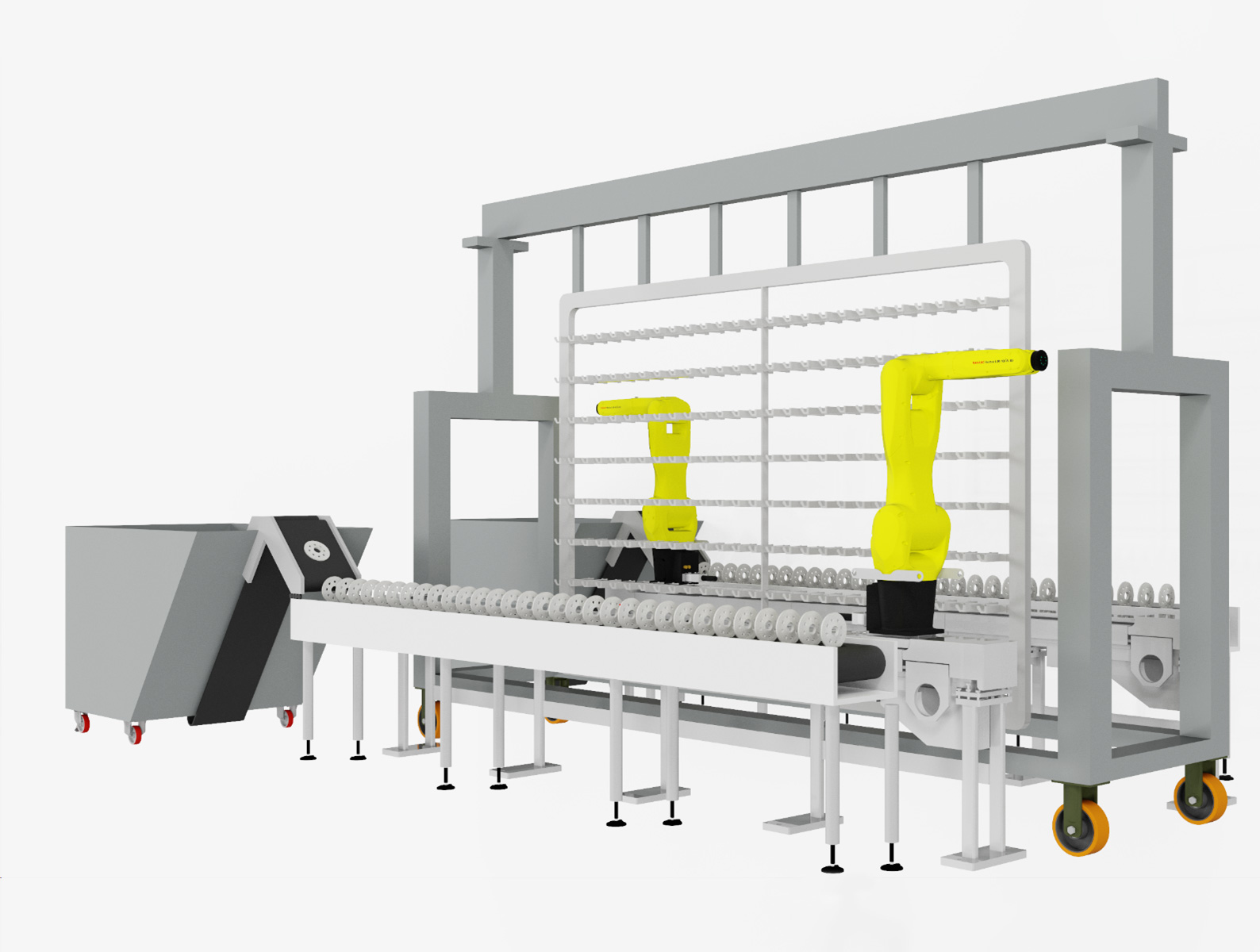

KabLaser is the business unit specialising in the design, development and supply of laser marking systems that can also be integrated into automated production solutions.

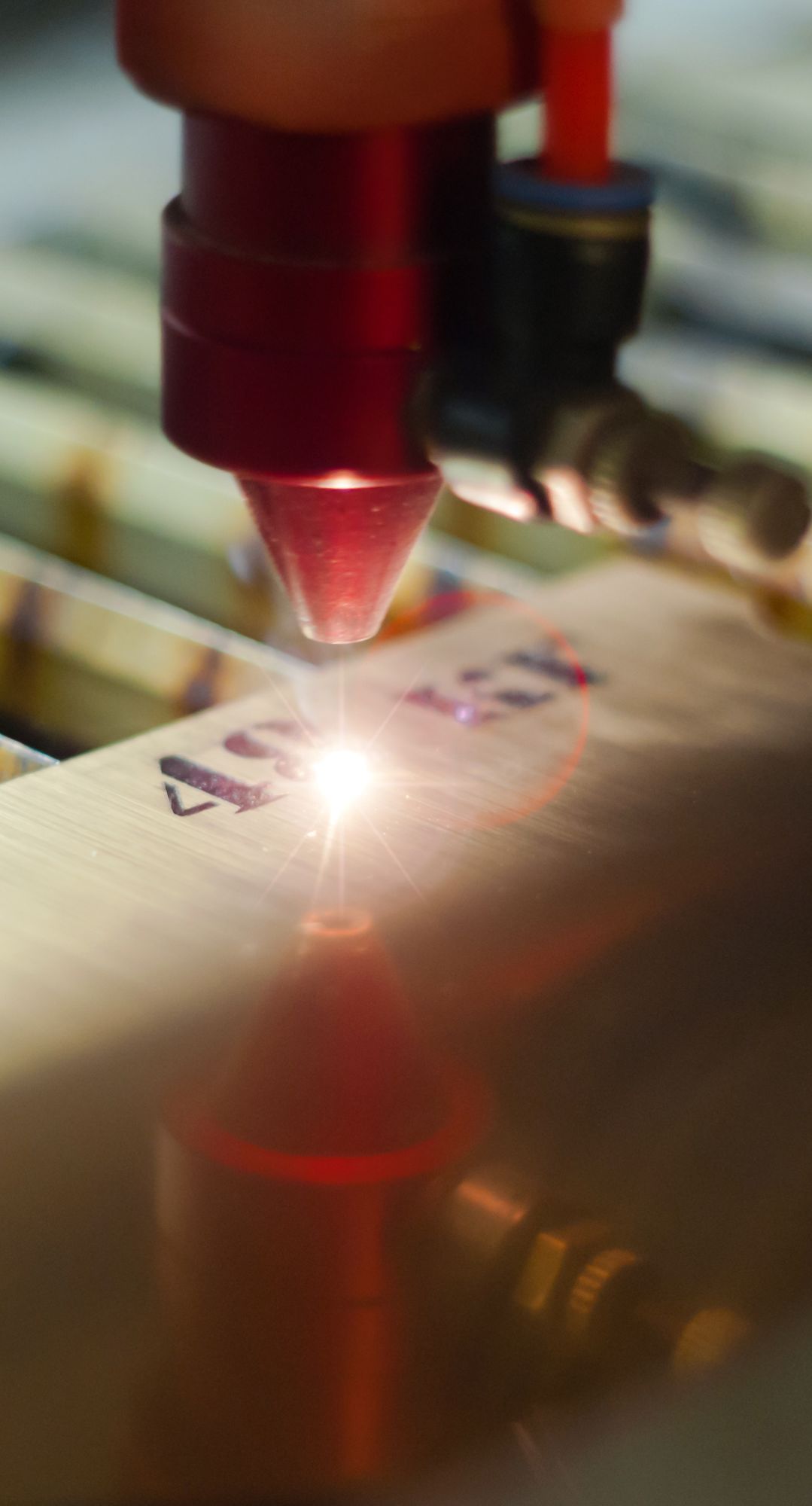

KabLaser machines can use different types of CO2, UV, etc. lasers, depending on the material to be engraved.

Automatic and robotic marking can be incorporated not only at the end of the line, but customised within the production stages.

KabLaser machines engrave on any material.

Discover the Benefits

We have also developed some laser marking machines specifically for marking glasses and goblets.

Optimising resources and increasing production capacity

The use of our machines makes it possible to cut time schedules, save resources, schedule ‘just in time’ production and reduce labour in favour of higher productivity.

Raising the value of human capital

Thanks to the automation of industrial processes, employees will have more relevant roles within the company, leaving the most dangerous, repetitive and alienating roles to the machines.

Competitiveness in the industry

The increase in productivity due to the use of autonomous machines with innovative state-of-the-art technology allows the company to gain competitiveness in the market.

Ease of use

Thanks to the intuitive man/machine interface, productivity monitoring app and staff training.

For all materials

for metals, organic materials, plastics and other materials.

Various technologies

fibre, CO2, UV to allow any application scenario to be successfully solved.

Discover the KabLaser products

KABLASER GL05

UV laser marking machine with translation table for glass products.

Fully automatic, fully digital, 4.0 interconnection.

Case Study

Discover how KabLaser technology can be used

Discover case studies and success stories from our customers.

How Kablator technology has improved the production processes of companies that have invested in the future of industry.

See all